Con

RMS Regular

- Thread Starter

- #26

With a bit of free time over Xmas I can update with a How To sort of for folks if they want to give it a bash.

So firstly obviously find a panel you would like to Carbon skin.

In this case I a plastic door card insert but a dash piece or mirror cover or bonnet is the same process.

These door tops are usually covered in a vinyl or various materials. This needs stripped off back to the bare plastic, I find a wallpaper stripper really good to shave it all off.

28 Year old 90s Honda contact adhesive is easy to remove.

Seen here in bare plastic form along with some speed shapes...again using the same process skinning or overlay.

Once you have your part ready it's time to make a mechanical lock for the Epoxy Resin to adhere to.

Exactly the same as keying for a clear coat scoring up for a good bite between materials.

I like to use a tool with 4 Stanley blades together to get 4 score lines at as time, the more key marks the better the bite.

On dash trims and parts that have had wax or silicone polishes on top in past...this is important to get a good bite and remove all contaminants as the same with paint, will fish eye and cause problems down the line.

Panel wipe and tack clothes are your friend to remove all particles.

Stage 2 is Epoxy Resin Time.

I use XCR Black Epoxy

www.easycomposites.co.uk

www.easycomposites.co.uk

For a part like these speed shapes which are white there is a high chance the white will show through and generally most parts are black or somewhere in between.

So it's good practice to use a Black tinted Epoxy resin that way your covered and have a good flat base colour for your fabric to overlay.

So...2 Part Epoxy A & B which is black

Weigh out amounts of both usually around 4:1 so 25g for part A and 10G Hardener

For about 30x30cm area 35g using a normal paint brush, spread it on thinly in stipple into crevices and edges.

Once the layer has reached B Stage, this is where its tacky and when touched doesn't leave residue.

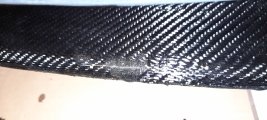

Your ready to lay the fabric, in this case Carbon 2x2 Diagonal twill 210gsm is used.

2x2 is the weave setup over lapping the fibres.

Some fabric is listed at 3k, 6k 12k.

The K is the Thousands of individual strands of carbon.

So a higher number means more strands which is thicker fabric.

A thicker fabric is stronger but...the caveat is its stiffer in raw form so...it's harder to lay into curves and more expensive.

Generally the average Carbon bonnet will have a thin 210gsm 3k or 4k visual layer.

TOP TIP: Use the removed cover as a template or masking tape to avoid waste

Lay the fabric flat and smooth out as much as possible working from the middle out wards like vinyl wrapping.

Tuck edges with tape making sure there is good contact and secure on backside.

From this stage you can throw it into a vac bag to pull pressure and hold the fabric tightly until it cures. Usually around 12-24 hours.

I use a composites vac pump but there have been good results posted online of folks using the clothing bags for the normal trusty hoover.

So firstly obviously find a panel you would like to Carbon skin.

In this case I a plastic door card insert but a dash piece or mirror cover or bonnet is the same process.

These door tops are usually covered in a vinyl or various materials. This needs stripped off back to the bare plastic, I find a wallpaper stripper really good to shave it all off.

28 Year old 90s Honda contact adhesive is easy to remove.

Seen here in bare plastic form along with some speed shapes...again using the same process skinning or overlay.

Once you have your part ready it's time to make a mechanical lock for the Epoxy Resin to adhere to.

Exactly the same as keying for a clear coat scoring up for a good bite between materials.

I like to use a tool with 4 Stanley blades together to get 4 score lines at as time, the more key marks the better the bite.

On dash trims and parts that have had wax or silicone polishes on top in past...this is important to get a good bite and remove all contaminants as the same with paint, will fish eye and cause problems down the line.

Panel wipe and tack clothes are your friend to remove all particles.

Stage 2 is Epoxy Resin Time.

I use XCR Black Epoxy

XCR Black Epoxy Basecoat - Easy Composites

Intense black colour, fast curing epoxy 'basecoat' for use in the carbon fibre skinning process. Buy online, expert support & UK next-day/fast EU shipping.

For a part like these speed shapes which are white there is a high chance the white will show through and generally most parts are black or somewhere in between.

So it's good practice to use a Black tinted Epoxy resin that way your covered and have a good flat base colour for your fabric to overlay.

So...2 Part Epoxy A & B which is black

Weigh out amounts of both usually around 4:1 so 25g for part A and 10G Hardener

For about 30x30cm area 35g using a normal paint brush, spread it on thinly in stipple into crevices and edges.

Once the layer has reached B Stage, this is where its tacky and when touched doesn't leave residue.

Your ready to lay the fabric, in this case Carbon 2x2 Diagonal twill 210gsm is used.

2x2 is the weave setup over lapping the fibres.

Some fabric is listed at 3k, 6k 12k.

The K is the Thousands of individual strands of carbon.

So a higher number means more strands which is thicker fabric.

A thicker fabric is stronger but...the caveat is its stiffer in raw form so...it's harder to lay into curves and more expensive.

Generally the average Carbon bonnet will have a thin 210gsm 3k or 4k visual layer.

TOP TIP: Use the removed cover as a template or masking tape to avoid waste

Lay the fabric flat and smooth out as much as possible working from the middle out wards like vinyl wrapping.

Tuck edges with tape making sure there is good contact and secure on backside.

From this stage you can throw it into a vac bag to pull pressure and hold the fabric tightly until it cures. Usually around 12-24 hours.

I use a composites vac pump but there have been good results posted online of folks using the clothing bags for the normal trusty hoover.